Engineers Develop Soft Robot That Can Carry Its Own Power Supply

For their work on a soft robotic system that can lift more than 200 times its weight, Adam Bilodeau, Prof. Rebecca Kramer-Bottiglio, and two collaborators at Columbia University were recently awarded Best Student Paper at the IEEE International Conference on Soft Robotics.

The paper, “All-Soft Material System for Strong Soft Actuators,” is based on work in Kramer-Bottiglio’s lab combining a heating composite they’ve developed with an actuator created in a lab at Columbia. The combination resulted in a new, silicone-based material that’s completely soft and electrically stimulated. It produces forces comparable to well-established pneumatically powered soft robots without the need for bulky components such as air compressors.

“Soft roboticists have been searching for new actuator technologies,” said Kramer-Bottiglio, assistant professor of mechanical engineering & materials science. She and Adam Bilodeau, a graduate researcher, worked on the system with Columbia roboticists Hod Lipson and Aslan Miriyev. The Columbia lab had previously developed a new actuator – a device that turns energy into mechanical work – made from silicone that expands when heated. A rigid wire running through the material served as the heat source.

The researchers improved upon this material system by replacing the rigid wire with a low-cost, Joule heating silicone developed in Kramer-Bottiglio’s lab. By mixing a conductive filler with the silicone, they created a rubber material that conducts electricity with just enough resistance to convert the electric power into heat. The heating composite was integrated into the actuator using various designs, allowing the heat to spread evenly throughout the actuator and likely enhancing the efficiency of the heater over the previous design.

“It’s a way of taking that heater wire and replacing it with something much more effective,” Bilodeau said.

The heating composite also improves on the previous design because it can be 3D printed. This opens up numerous possibilities for building new, complex material actuators with increased efficiency. Because both the heating material from Yale and the actuator from Columbia have similar chemistry – both are silicone rubber – there’s a compatibility between the two that enhances the printability of the entire system.

“We’re looking to integrate both materials more intricately in the future,” Kramer-Bottiglio said, adding that the distribution of the heating material would resemble “veins and capillaries throughout the system.”

Depending on how they pattern the heating material into the actuator material, she said, there’s the potential to use it as both a heater and a sensor. “We’re working towards multi-functional soft materials, and we’re grateful that this contribution was recognized by the soft robotics community,” Kramer-Bottiglio said.

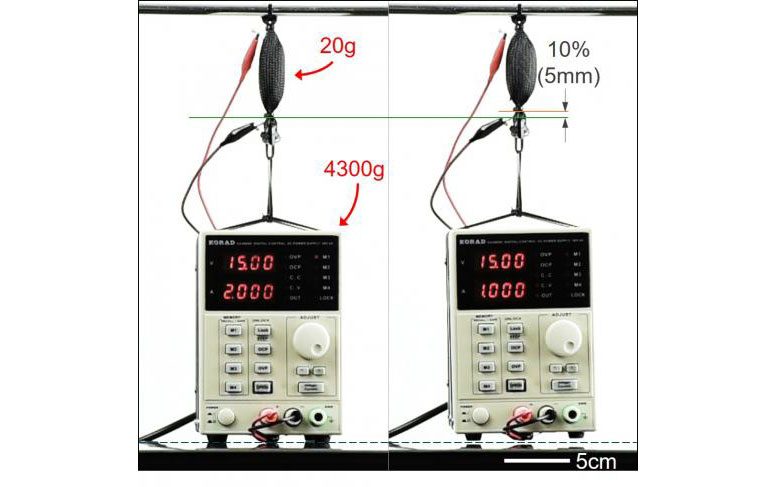

Securing the researchers’ confidence in the system was its ability to lift its own power supply – more than 200 times its own weight – a feat of strength unheard of in the soft robotics field.

In general, soft robotics holds great promise for numerous applications, such as human-robot interaction (where safety is built in at the material level), soft exoskeletons and other wearable technologies, and resilient robots that can survive impacts and falls.

Your Opinion is valid .